[color=darkred:1193b6865e][/color:1193b6865e]

Hi All.....I have a H-Series Wide-Front end Farmall.

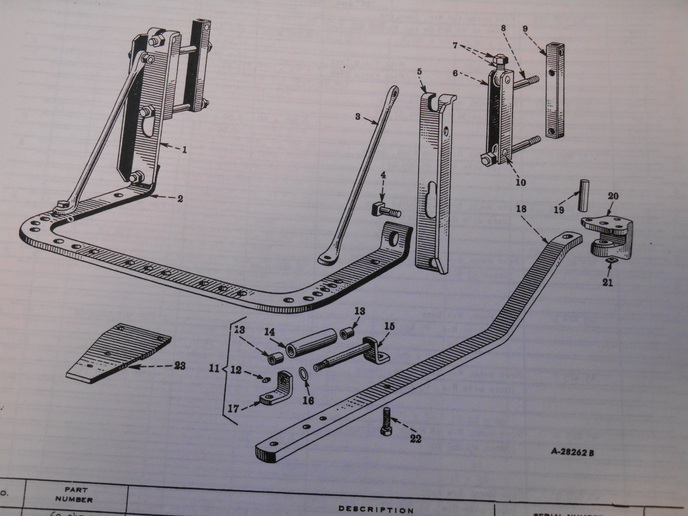

I would like to attach a Draw Bar on the back end. Is anyone

using a 52" 3/4 thick 2 1/2 wide bar?? I could provide a photo

of the Rear end section where it would be mounted that has 8 or 10 holes already pre-drilled into a frame.

I would like to be able to attach a Chain to this draw bar for general use like pulling logs out of the woods.

I'm not sure just how it would attach to the underside of the Tractor....

Thank you for your Reply....Ron (Maine)

Hi All.....I have a H-Series Wide-Front end Farmall.

I would like to attach a Draw Bar on the back end. Is anyone

using a 52" 3/4 thick 2 1/2 wide bar?? I could provide a photo

of the Rear end section where it would be mounted that has 8 or 10 holes already pre-drilled into a frame.

I would like to be able to attach a Chain to this draw bar for general use like pulling logs out of the woods.

I'm not sure just how it would attach to the underside of the Tractor....

Thank you for your Reply....Ron (Maine)