You should upgrade or use an alternative browser.

- Thread starter mmack

- Start date

old

Well-known Member

- Location

- Camdenton Missouri

gene bender

Well-known Member

James Williams

Well-known Member

jimmy

rustyfarmall

Well-known Member

(quoted from post at 11:56:10 02/27/12) Ive got a 39 H soaking now with no luck,Ive broke a dozen of old tractors loose but mostly taping on top of the pistons,Im to the point if soaking with anything will lossen them,they werent stuck good in the first place.Here on the east coast I beleive the humitity is a lot worst than most place

jimmy

Exactly! If all it takes is some kind of magic potion poured in on top of the pistons, then the engine wasn't really stuck to begin with.

Dean Olson

Well-known Member

I was taught that you never pull a stuck motor as that can create more damage.

rustyfarmall

Well-known Member

Of course there is always the option of pulling the motor, removing the crank, and then use a BIG press to remove the pistons and sleeves as a unit. You can then break the sleeve and peel it away from the piston so you can remove the piston pin and salvage the connecting rods. New sleeves, pistons and a few other things and you've got a brand new motor.

(quoted from post at 13:18:46 02/27/12)

Of course there is always the option of pulling the motor, removing the crank, and then use a BIG press to remove the pistons and sleeves as a unit. You can then break the sleeve and peel it away from the piston so you can remove the piston pin and salvage the connecting rods. New sleeves, pistons and a few other things and you've got a brand new motor.

My grandpa will pull the crank (on flathead Fords, but the concept is the same) and then take blocks of oak and metal bars and use the bars pushing on the oak pushing on the pistons as a press. He will use penetrating oil of some sort in the process. He doesn't talk much and this is about all I know.

Edit - This is a long term thing. Like do this and then wait a few days or weeks and they will pop loose from the oil and constat pressure. Same concept as parking a tractor on a slight incline in fifth gear.

BTW, if I wasn't going to work on this project right now there is nothing to lose by pouring some diesel down the exhaust. Might as well start the process of breaking things free. ATF/Acetone or brake fluid are probably just as good, but not quite as cheap as diesel. There are probably a million other things that work, too.

were easily removed. I used a steam jenny on the engine block. The crankshaft measured .002"

undersize and my wife dropped it off at our local

auto machine shop. They called me at work and said the crankshaft only needed to be polished

and they had measured it .002" undersize. They furnished the bearings and they redid the head.

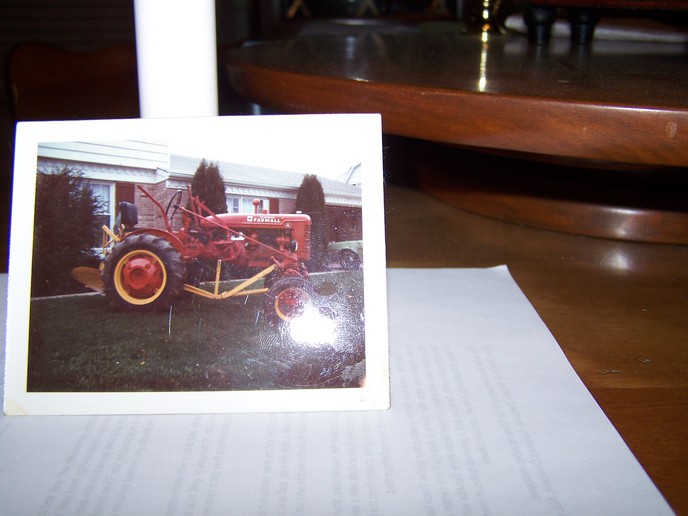

Had them to install the new pistons on the old rods. Bought the sleeve kit at our local IH dealer cost back then was $80.00. The tractor needed new tires, fenders, rims, steering wheel, seat and wiring. I gave $100.00 for the tractor and plow. I plowed the garden in the Spring of 1976. Hal

soaked engine with lots of things. tried turning with crank starter, screwdriver in ring gear, etc etc. pulled oil pan. put jack under rod bearing and jacked front of tractor completely off ground. then put screwdriver into ring gear to assist jack. it came unstuck and seems to be o k.

not recommending anything. it is your tractor. i figured mine was no good as it was.

1..Remove all, hood gas-tank, nose cowel, and radiator, Head and all wiring harness. Pan, oilpump, and rod caps. Have the tractor where you can roll it outside, CLEAR AREA OF GAS CANs, GREASE RAGS AND ALL FLAMMABLE THINGS!

tractor is now outside.

2..fill the cylinder with the most volume with Diesel add a splash of Gas, Set it on fire. Go get a cup of coffee and enjoy till the fire has burnt itself out. Take a block and a 4 lb sledge and drive the piston out from the bottom.

3.. repeat #2 on the next 3 pistons with the most volume. As you work your way down to the cylinders with the least volume the #of burning will go up to generate enough heat to pop the rust around the rings.

This method will allow you to at least inspect the piston and sleeve to see if they are salvageable.

***The first two usually go pretty quick the last 2 take a little longer.

***If motor is on a engine stand you can rotate the engine over for easier driving of the block.

Hope this helps!

Later,

John A.

(quoted from post at 16:06:22 02/27/12) mmack,Burn it out! This method will get the job done in one afternoon. Follow my direction here.

1..Remove all, hood gas-tank, nose cowel, and radiator, Head and all wiring harness. Pan, oilpump, and rod caps. Have the tractor where you can roll it outside, CLEAR AREA OF GAS CANs, GREASE RAGS AND ALL FLAMMABLE THINGS!

tractor is now outside.

2..fill the cylinder with the most volume with Diesel add a splash of Gas, Set it on fire. Go get a cup of coffee and enjoy till the fire has burnt itself out. Take a block and a 4 lb sledge and drive the piston out from the bottom.

3.. repeat #2 on the next 3 pistons with the most volume. As you work your way down to the cylinders with the least volume the #of burning will go up to generate enough heat to pop the rust around the rings.

This method will allow you to at least inspect the piston and sleeve to see if they are salvageable.

***The first two usually go pretty quick the last 2 take a little longer.

***If motor is on a engine stand you can rotate the engine over for easier driving of the block.

Hope this helps!

Later,

John A.

Don't the sleeves try to come out with the pistons when you beat up from the bottom? How do you not break the bottoms of the sleeves?

Zachary Hoyt

Well-known Member

come out good enough to use again, it all depends on how bad the

sleeve is to begin with. I always drive the pistons out from the

bottom after pulling the engine and flipping it over, sometimes the

sleeve comes with and sometimes it stays in the block.

Zach

old

Well-known Member

- Location

- Camdenton Missouri

gene bender

Well-known Member

fixed the problem. Hal

old

Well-known Member

- Location

- Camdenton Missouri

glennster

Well-known Member

Lee in Iowa

Member

Bill Krosnicki

Member

(quoted from post at 19:21:11 02/28/12) A guy around here that restores a lot of tractors got something made he could screw into the spark plug hole and hook a hydraulic hose from another tractor to and put pressure on that way.

That's like putting a hydraulic cylinder inside your engine, seems like a good way to break something!

rustyfarmall

Well-known Member

(quoted from post at 11:21:11 02/28/12) A guy around here that restores a lot of tractors got something made he could screw into the spark plug hole and hook a hydraulic hose from another tractor to and put pressure on that way.

That system does work. I've seen it in action, but I don't know just how badly the engine was stuck. I've even tried it myself, but was NOT successful because the valves were stuck open also and all I did was pump hydraulic oil into the exhaust manifold.

To do it right, you need to use a tractor with a 2-way hydraulic system, and have the hoses connected to 2 different engine cylinders.

The adapter is relatively easy to make. Just knock the center out of a couple of spark plugs and weld in a hose coupler.

old

Well-known Member

- Location

- Camdenton Missouri

Similar threads

- Replies

- 13

- Views

- 450

- Replies

- 3

- Views

- 560

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy