Hi, all. I just bought a W-9 project and want to establish what I

have to work with before spending a lot on it. It"s been stored

inside, the engine is loose, and it turns over nicely with its rebuilt

starter.

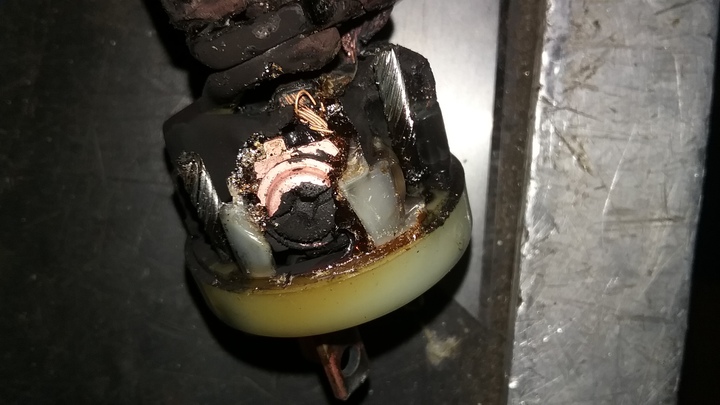

It doesn"t have spark, and has a 12 volt conversion (single wire

alternator) with magneto. The seller said it was as if someone had

converted the mag into a distributor. The magneto has 2 external

Farmall style condensers and a standard cylindrical coil outside

(the mag"s coil is probably bad). The wiring is rough and one wire

is pulled out of a condenser.

It has a couple of toggle switches, one is spring loaded and works

as the starter switch (via solenoid). I figure the other is the kill

switch, but there is also has a strange plastic switch that looks

something like the plastic key switch on a snow blower.

I have several pictures that I would be glad to e-mail anyone who

might be able to give me some ideas. Again, at this point I"d just

like to see if I can make it fire and run. Eventually, I"ll clean up the

wiring and hopefully get a correct coil for the mag. Any ideas on

this setup?

Thanks for reading,

zim

have to work with before spending a lot on it. It"s been stored

inside, the engine is loose, and it turns over nicely with its rebuilt

starter.

It doesn"t have spark, and has a 12 volt conversion (single wire

alternator) with magneto. The seller said it was as if someone had

converted the mag into a distributor. The magneto has 2 external

Farmall style condensers and a standard cylindrical coil outside

(the mag"s coil is probably bad). The wiring is rough and one wire

is pulled out of a condenser.

It has a couple of toggle switches, one is spring loaded and works

as the starter switch (via solenoid). I figure the other is the kill

switch, but there is also has a strange plastic switch that looks

something like the plastic key switch on a snow blower.

I have several pictures that I would be glad to e-mail anyone who

might be able to give me some ideas. Again, at this point I"d just

like to see if I can make it fire and run. Eventually, I"ll clean up the

wiring and hopefully get a correct coil for the mag. Any ideas on

this setup?

Thanks for reading,

zim