Couple years ago Dad & myself picked up a H in southwestern Minnesota. It has a 6ft belly mower, going to use mow around 1/4 mile of new trees that were planted around the old barn yard. All of last year was spent building a shop, so the H had to wait for some TLC. Farmall tractors are not very common in Western Canada, mostly the W line. My Grandfather used to have a H after the war, its long gone. Found a H with a belly mower, since it coming across the border. The paper work has to be all in place before crossing. So if the tractor was not what we wanted, cant bring a different one across at that moment. So were stuck with it, also came 1200 miles one way.

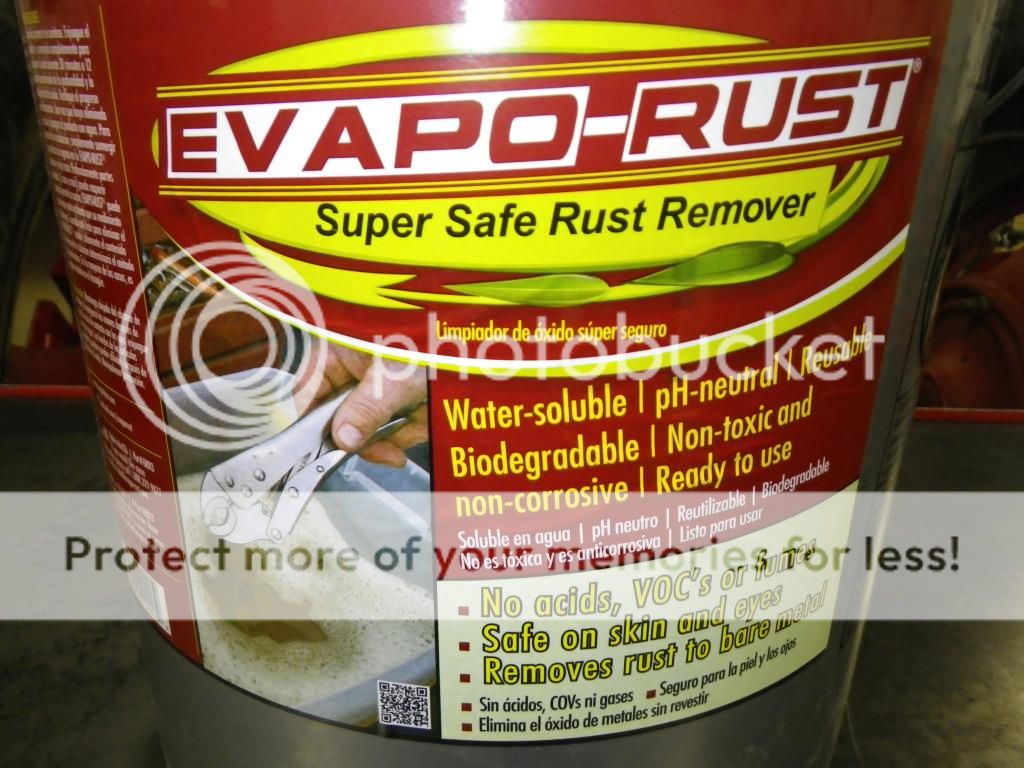

Now its 2014, finally get to work on the H. Did the typical things, tune up, oil change, etc. Get it running okay, take out to mow the grass. Its overheating, notice water pump is leaking. Tried to get the belt off, tapping on pulley, it breaks. Get new water pump, have the rad cleaned out. Put back together, still overheating. I hooked up pressure washer to the port under the carb that goes into the cooling system. Had the water pump out. Was at car wash for a hour or more. Figured its good now, nope. Got a pail of evapo-rust, put that in the cooling system. Still over heats, removed the plate on the side of the block, its full of scale. Other than removing the engine, then having the block cleaned in caustic cleaner. Does anybody have ideas?

Now its 2014, finally get to work on the H. Did the typical things, tune up, oil change, etc. Get it running okay, take out to mow the grass. Its overheating, notice water pump is leaking. Tried to get the belt off, tapping on pulley, it breaks. Get new water pump, have the rad cleaned out. Put back together, still overheating. I hooked up pressure washer to the port under the carb that goes into the cooling system. Had the water pump out. Was at car wash for a hour or more. Figured its good now, nope. Got a pail of evapo-rust, put that in the cooling system. Still over heats, removed the plate on the side of the block, its full of scale. Other than removing the engine, then having the block cleaned in caustic cleaner. Does anybody have ideas?