Canadian Ken

Member

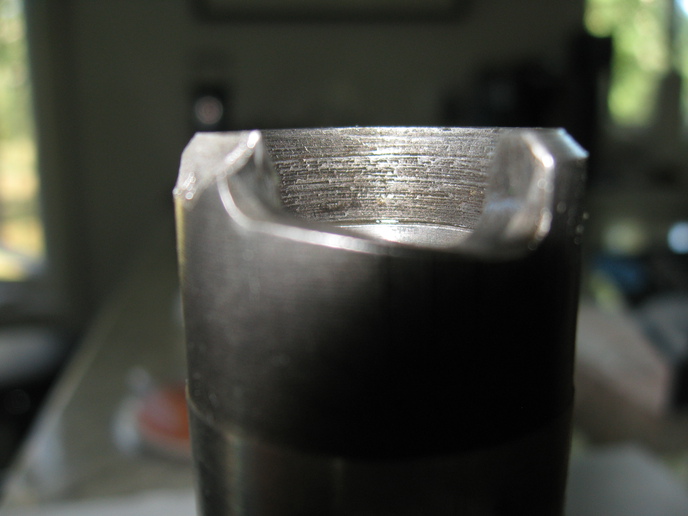

Assembled the cams, shaft, spring held in place with the nut, not tightened to original tension -the wear on the cam stud/rod -when the moveable cam is turned, the corners catch on the stationary cam -slid the assembly in the sleev and rotated it with vice grip attached to non machined surface -the shaft had a distinct catch everytime rotated - will try with spring properly tensioned -my thought is that the moveable cam bore is quite loose on the rod/stud in additional to the wear groove on the stud and wear inside sleeve allows cam to tilt enough so that the corners catch while rotating -I will clean up all the surfaces -remove burrs and level out divots -ordered new dowel pins even though very little wear on present ones -and flip the rod/stud end for end to get vway from the wear groove and try rotation--

Are the corners of the moveable cam supposed to be beveled or square -bevelled due to wear?

Best tool to use fine file, emery cloth, stone -?

Ken

Are the corners of the moveable cam supposed to be beveled or square -bevelled due to wear?

Best tool to use fine file, emery cloth, stone -?

Ken