Mike Henry

Member

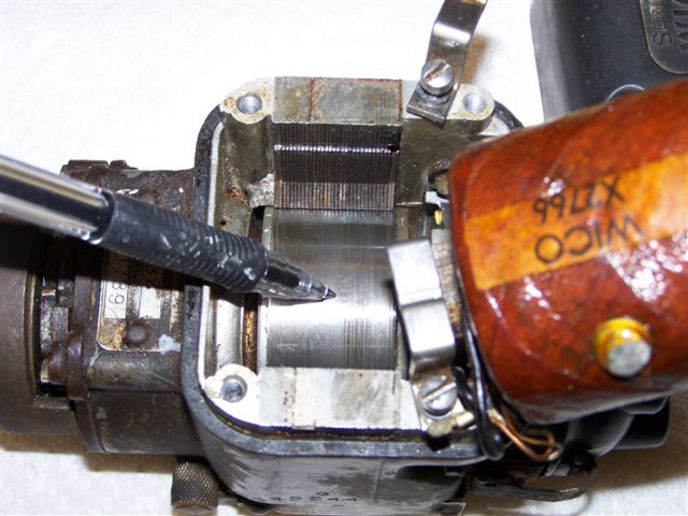

Thanks for the confirmation on how to remove the mag.Couple of you mentioned to check spark after the tractor quit. We have done that it is weak at best. Some mention the coil.I was thinking the coil is inside the mag. The plug wires come right to the cap on the mag. It dont have a coil (as I would recognize it). What would I be looking for? I picture a coil being a black tubular thing that mounts near the mag or distributor that has a plug wire going to the top of it.It is usually held in place with a metal band.I need more knowledge, I guess. Anything will be appreciated. Thanks again.

MIKE

MIKE