Walt in Jaxn Tn.

Well-known Member

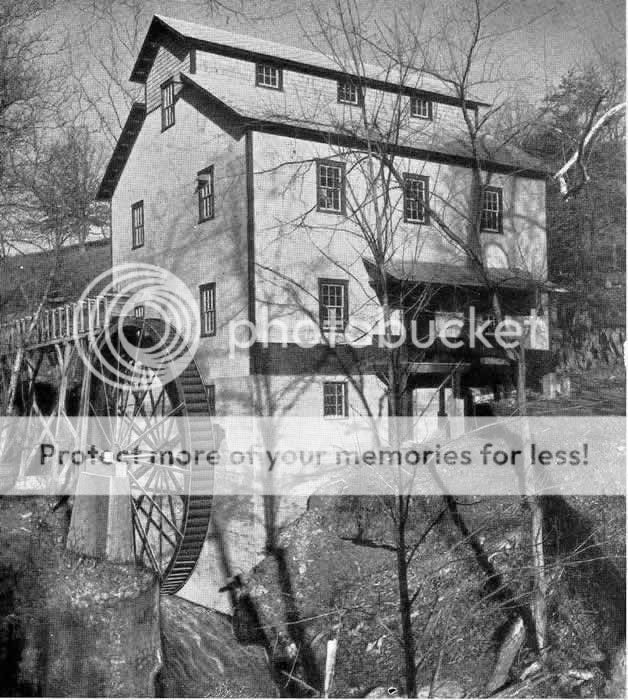

This is what I saw just south of Savannah Tn. on a county road. It's a Leffel turbine. I recognized it because I saw one just like it in use at the Alley Mill just west of Eminence Mo.

The Alley Mill turbine is about 4 ft. across at it's widest point and develops 120 H.P. from the big pulley on top of the turbine. This turbine is about 5 ft. across at it's widest point.

While you are looking at these photos, remember that the spring water that comes out the Alley Spring is a constant 59 to 61 degrees summer and winter. That thought ought cool you while you're looking.

The Alley Mill turbine is about 4 ft. across at it's widest point and develops 120 H.P. from the big pulley on top of the turbine. This turbine is about 5 ft. across at it's widest point.

While you are looking at these photos, remember that the spring water that comes out the Alley Spring is a constant 59 to 61 degrees summer and winter. That thought ought cool you while you're looking.