MichiganMH

Member

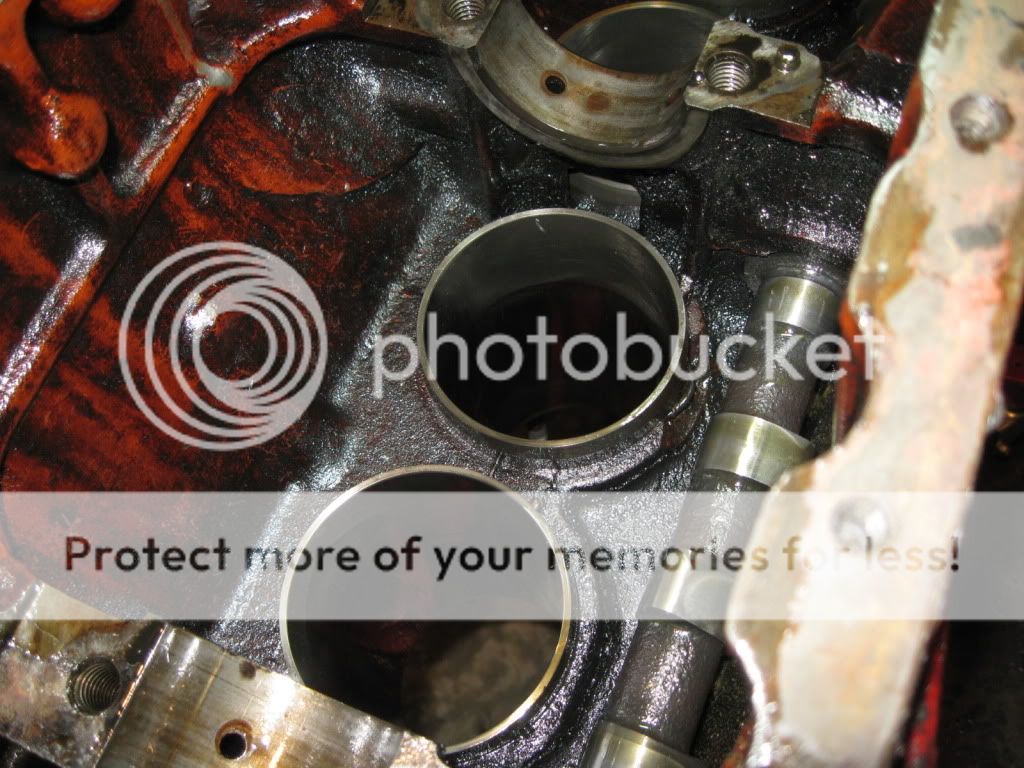

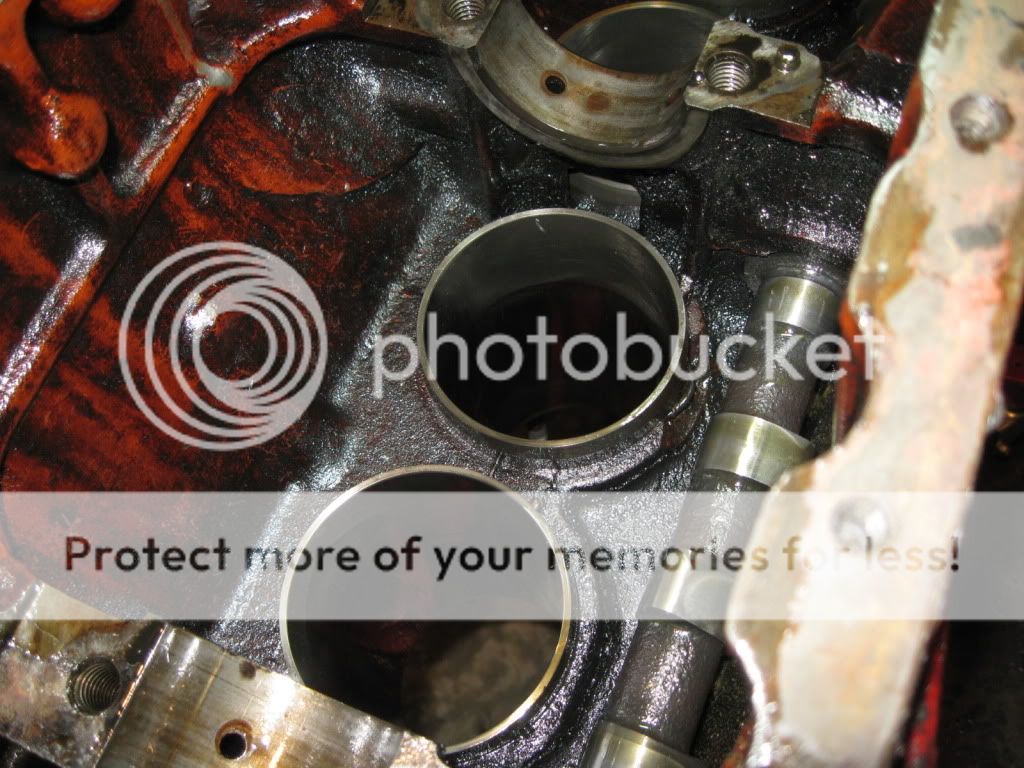

Rebuilding the Z134 in my MH50. Sometime in it's past life it must have busted a rod. The block has a piece missing at the bottom of one sleeve, exposing the lower o-ring. I never had a problem with water in the oil, but had low compression, that's why it is being rebuilt. I am considering trying to get it welded, then get it on a CNC and re cut the bore and o-ring groove, but it may just be cheaper to find another block as I will have to pay a weld shop, and probably for CNC time as well. Anyone else try to repair something like this? Is there another way to repair this? Anyone have a Z134 block for sale near Michigan :lol: