Bill from Scotland

Member

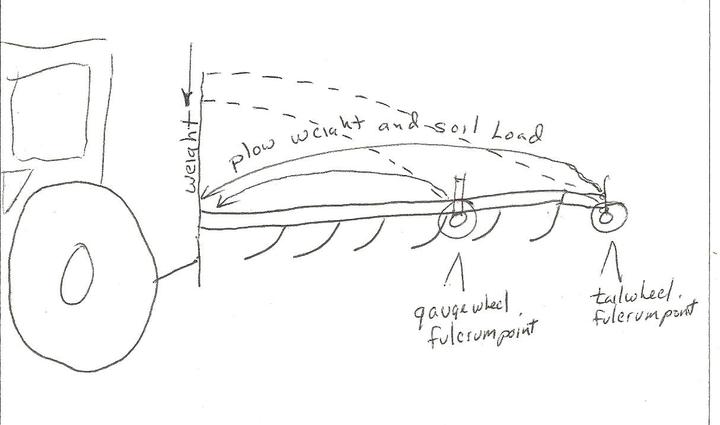

I posted earlier showing my first attempt at plowing with the MF 1155 and 880 6 bottom plow. It seemed to work okay but Im sure I could do better with the set up and operation. I have attached several pictures showing part of the plow as well as tractor controls, I need advice on these.

Am I correct in saying the adjustment nut for the rear wheel can help with setting depth at the rear of the plow?

I have now managed to adjust the plow a little toward the left which I guessing should help increase the width of the first furrow which was too narrow.

The next picture shows the auxilary control lever and valve adjustment, Ive been using this to raise and lower the rear of the plow.

The following pictures shows hydrolic control quadrant. Ive been using this to raise and lower the front of the plow and to set depth at front.I dont think Ive been using this as I should.

Havent done anything with the control selector lever and dont really know what effect this should have or where it should be set.

Last picture shows draft depth control wheel, again I havent used this.

What I need you guys to do is guide me through what you would do and how to adjust the various controls from the stage of droping the plow to getting the draft control etc operating as it should.

The last picture shows the accumulator which I attached to the hydrolics when charging the auto trips. This was then disconnected but Im not sure if needs connected all the time.

Any help or advice much appreciated.

Thanks

Bill

Am I correct in saying the adjustment nut for the rear wheel can help with setting depth at the rear of the plow?

I have now managed to adjust the plow a little toward the left which I guessing should help increase the width of the first furrow which was too narrow.

The next picture shows the auxilary control lever and valve adjustment, Ive been using this to raise and lower the rear of the plow.

The following pictures shows hydrolic control quadrant. Ive been using this to raise and lower the front of the plow and to set depth at front.I dont think Ive been using this as I should.

Havent done anything with the control selector lever and dont really know what effect this should have or where it should be set.

Last picture shows draft depth control wheel, again I havent used this.

What I need you guys to do is guide me through what you would do and how to adjust the various controls from the stage of droping the plow to getting the draft control etc operating as it should.

The last picture shows the accumulator which I attached to the hydrolics when charging the auto trips. This was then disconnected but Im not sure if needs connected all the time.

Any help or advice much appreciated.

Thanks

Bill