Bryce Frazier

Well-known Member

Alright, so I got this wagon home and have been doing some work to it. The steering is finally starting to free up, and the more I pull it around the better it gets!

I have been trying to ID it, and I made a major break through yesterday. I found 4 holes on the back of the rear axle where there was clearly a plate at one time. I went back to my previous post about Farm Wagons, and many of you said that is where the tag would be if it was a David Bradly, made by Electric Wheel Co.

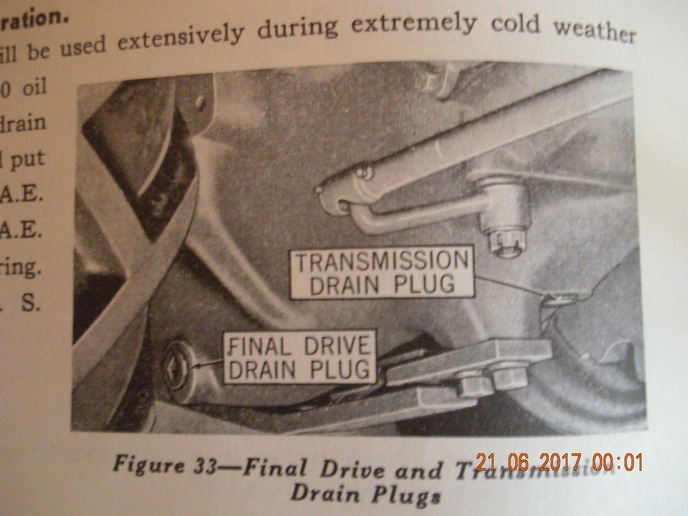

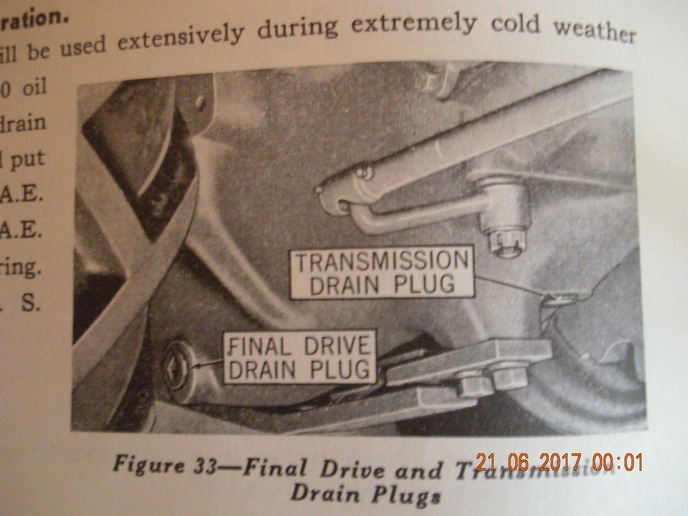

While looking at the post, I remembered the picture of the wagon that i posted that was for sale on CL (1st picture here) I looked at it and it is nearly the exact same wagon as the one I got home!!! (2nd picture here)

So, here is what I am seeing is wrong with mine... You will notice on the first wagon, that there is a cross bar ON TOP of the front axle that has the holders for 4 x 6's on it.

When you look at mine, my brackets are just welded to the axle? Mine doesn't have that big block on top of the front axle like the other one does?

When I stepped back and looked at the wagon, it looks like if I was to lay a 2 x 4 (or whatever) between the front axle and the rear axle, and then put a level on it, it looks like the 2 x 4 would be sloping down towards the front of the wagon, which is NOT going to work if I am going to put a flat bed on it for bales... What should I do?

Also, what tonnage of running gear do you think I have? 6 x 15 tires, 5 bolt rims. I am thinking probably 4 ton? 2000lbs per wheel? Bryce

I have been trying to ID it, and I made a major break through yesterday. I found 4 holes on the back of the rear axle where there was clearly a plate at one time. I went back to my previous post about Farm Wagons, and many of you said that is where the tag would be if it was a David Bradly, made by Electric Wheel Co.

While looking at the post, I remembered the picture of the wagon that i posted that was for sale on CL (1st picture here) I looked at it and it is nearly the exact same wagon as the one I got home!!! (2nd picture here)

So, here is what I am seeing is wrong with mine... You will notice on the first wagon, that there is a cross bar ON TOP of the front axle that has the holders for 4 x 6's on it.

When you look at mine, my brackets are just welded to the axle? Mine doesn't have that big block on top of the front axle like the other one does?

When I stepped back and looked at the wagon, it looks like if I was to lay a 2 x 4 (or whatever) between the front axle and the rear axle, and then put a level on it, it looks like the 2 x 4 would be sloping down towards the front of the wagon, which is NOT going to work if I am going to put a flat bed on it for bales... What should I do?

Also, what tonnage of running gear do you think I have? 6 x 15 tires, 5 bolt rims. I am thinking probably 4 ton? 2000lbs per wheel? Bryce