You should upgrade or use an alternative browser.

- Thread starter SVcummins

- Start date

I would have poured them in 1976 or 77. So they have lasted 40 years or so now.

olgentdc

Well-known Member

Traditional Farmer

Well-known Member

- Location

- Virginia

Kansas4010

Well-known Member

Russ from MN

Well-known Member

- Location

- Bemidji MN

Now that I know they are classic Firestone I wonder if they have any value ? I was bolting them in my pick-up for winter weight. I hooked them to the gooseneck hitch in the bed.

fixerupper

Well-known Member

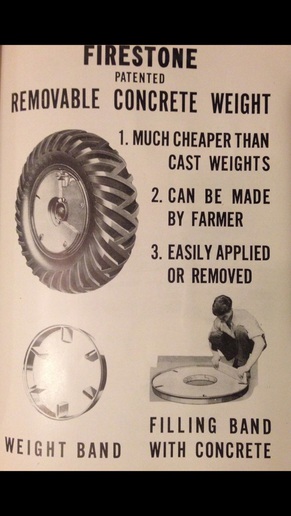

Back to original topic, concrete weights are lowest cost per pound, seen lots of guys try to pour concrete weights for garden tractors. With the lighter weight per cubic foot they ended up sticking out of the wheels about a foot. Most small loader tractors like 2404 IH, Case 420 Construction King, N-series Fords had home-made concrete blocks hanging on the 3-point to counter-balance the loaders. Sometimes a 55 gallon barrel filled with concrete was used instead. Yard of concrete in mid-1970's when I hauled it was 3800# and about $60.

Thomasthetankengine

Member

<image src="http://forums.yesterdaystractors.com/photos/mvphoto13349.jpg"/>

The thing with a Ford SOS is to understand what they are doing. When they are shifting two packs at once they will shift hard. IF you use the inching pedal during that shift it smooth it out. I also tried to never shift those gears under heavy load.

What that Ford 6000 did do was make me hate Ford's parts system. Next day was unheard of. Next week was more like it normally was. Plus the fact that even though the Ford 6000 was a 1964 model and I bought it in the mid 1970s many parts where not available already for it. It was barely ten years old at the time. I never even considered a Ford tractor after that for one of my serious working tractors.

My other tractor at that time was a JD "G". I could get just about anything I wanted or needed for it even with it being 30 years old at the time.

Similar threads

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy