I went looking for a baler a year or so ago and settled on a NH 315. It is the real deal as far as older square balers go. Meant to handle volume.....for example, twine box holds 3 spools vs. 2. This is what it did for me earlier this year.....

Agree with everything the others have said about it's ability, etc. I have used 3 tractors on it. Last year, the neighbor's 1100 Massey.....and that was a dream. The Massey has near perfect gear range for baling....with a high low range to step it up and down for the windrow.....plus it has the heft to handle it. The whole experience was smooth as silk.

Since then, I bought a Ford 5610 and baled with it this year. Handled it ok, but you knew it was back there. I also pulled it out earlier with the D15 Allis to rebale some loose busted bales in a stack. Sitting still, baler was rocking the D15 several inches per stroke......I would not want to bale with it. Would not be kind to the old girl. A D17 would be a better fit. I know a guy with a White 2-70 I'm trying to goad into letting me try on it.......purely for educational purposes you understand.

As for what to do.....if the baler has been sitting in the barn for a few years, you appear to have two paths to follow. The high risk plan is to assume it was baling OK when last used and would do so again. Grease it and go.

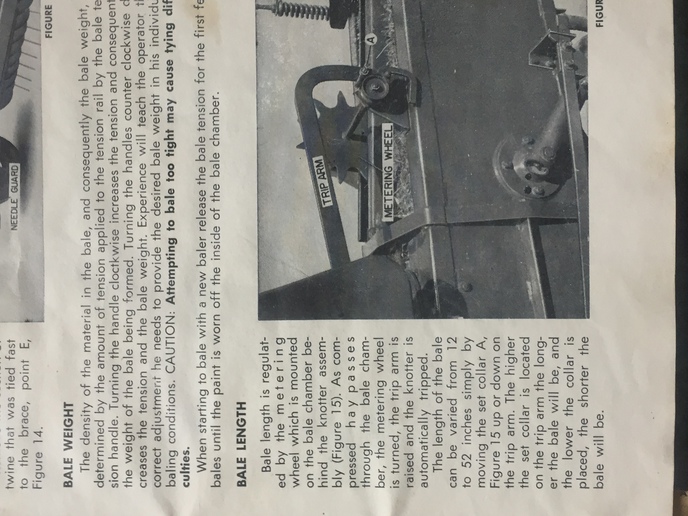

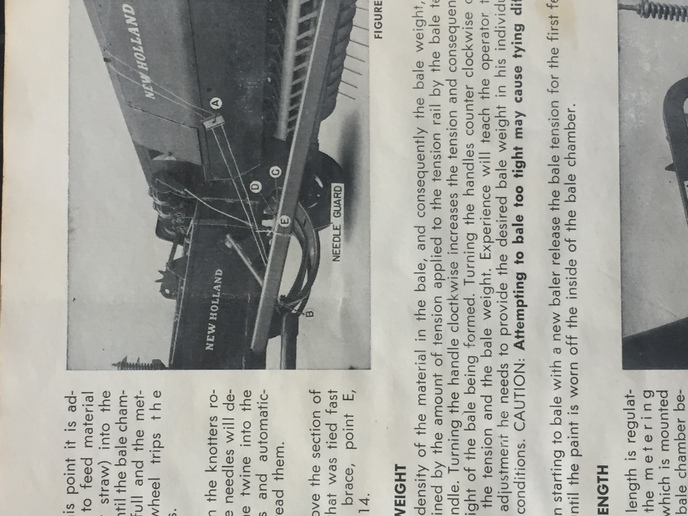

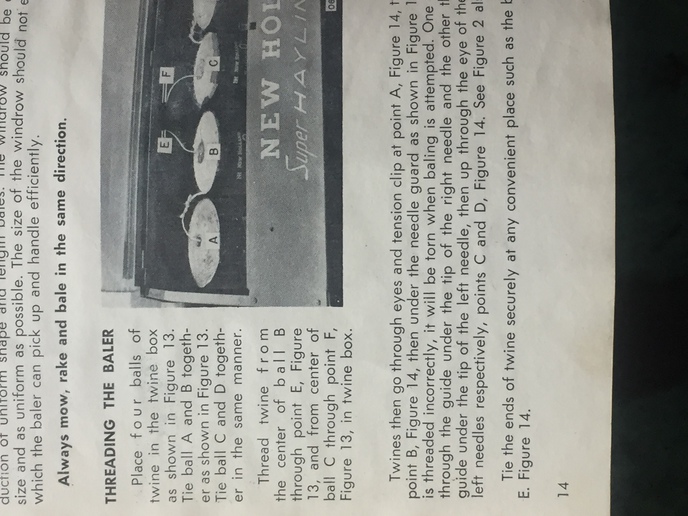

Safer plan is to take no chances, at the minimum, pull the old hay out, turn it over by hand to make sure all is working ok, trip the knotters while someone is turning it over by hand to see if it ties good knots. BTW, if the twine that was in it was sisal, I'd assume it is rotted enough I would start over with fresh. Sisal or plastic will work ok.......just get the 170# plastic.....not the thin stuff used in round balers. Basically do a full walk through to recommission it. When they are working right, they will spit bales out one after another with no worries. But when something goes wrong, it goes wrong in spectacular fashion.

Mine kept breaking shear pins......and while I was able to figure it out and get it working right, I decided to bring in a better set of eyes than mine to go over it. Good that I did as it was in need of some attention. In all, three guys with about 150 years combined experience between them helped me go through the entire baler......replaced plunger knives (and set knife clearance to specs)...... replaced plunger bearings......went through the knotters, timed the needles, checked slip clutches to make sure they would slip before something broke, etc.....in short, is back to almost new condition and it behaves as such.

Bottom line is you have assumed stewardship of a dang nice baler........it you do your part, it will spit out bricks.