jon f mn

Well-known Member

We sell a lot of 10' containers to contractors to store tools in,

but the shortest that can be shipped in ship or train is 20'. So

they come 20' and we have to cut them in half and put the

ends in.

I cut them apart with a plasma cutter

Then cut off the plates they weld in for filler.

The ends come inside against the side.

The worst part is grinding off all that crappy paint, it's like putty. Then tack in the ends and weld.

All done

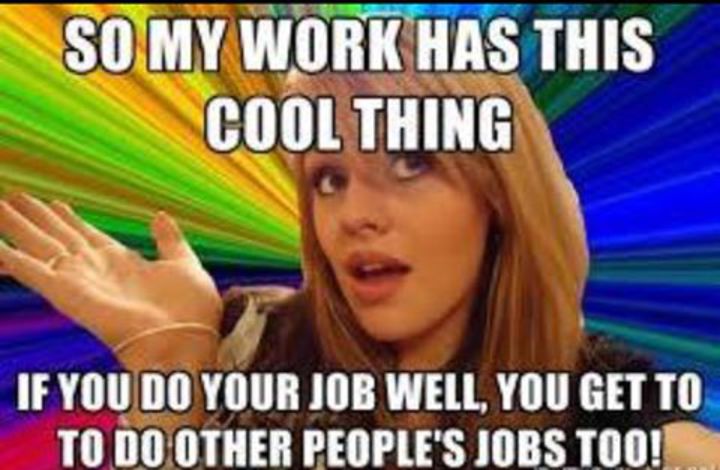

Next week I'll spend a day at the main shop working with their guys to teach them how to do it faster. They have done a lot of them and they take 14-16 hours to do them. I did the first one in 12 hours and the second in under 8. Lol. Now I have to be a teacher. Not sure I'll be any good at that.

but the shortest that can be shipped in ship or train is 20'. So

they come 20' and we have to cut them in half and put the

ends in.

I cut them apart with a plasma cutter

Then cut off the plates they weld in for filler.

The ends come inside against the side.

The worst part is grinding off all that crappy paint, it's like putty. Then tack in the ends and weld.

All done

Next week I'll spend a day at the main shop working with their guys to teach them how to do it faster. They have done a lot of them and they take 14-16 hours to do them. I did the first one in 12 hours and the second in under 8. Lol. Now I have to be a teacher. Not sure I'll be any good at that.