Back on page 2, Geo-TH,In made a electrical challenge...."I throw out the challenge for anyone showing a a 12 inverter Powering a 2 hp air compressor. Or for that matter any air compressor.".

I'm posting this in a new thread because he may not go back to page two where I replied that I'd accept his challenge.

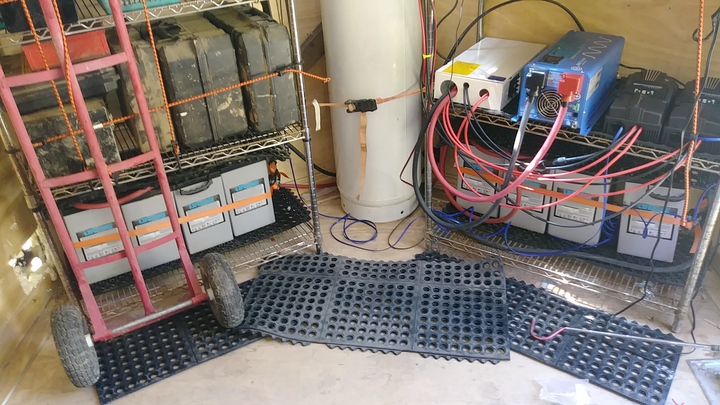

Anyway, I made a video of hooking my DeWalt 120 volt 1.6 hp 15 gallon air compressor to my 12 volt inverter and powering it up and running it. As I opened my cargo trailer door to show the cloudy skies my thumb slide across the "End" button on my tablet. That is why the video ended so abruptly.

So, George, it looks like your challenge was proven wrong and seems like someone can successfully run a air compressor from a 12 volt inverter.

Here you go George

I'm posting this in a new thread because he may not go back to page two where I replied that I'd accept his challenge.

Anyway, I made a video of hooking my DeWalt 120 volt 1.6 hp 15 gallon air compressor to my 12 volt inverter and powering it up and running it. As I opened my cargo trailer door to show the cloudy skies my thumb slide across the "End" button on my tablet. That is why the video ended so abruptly.

So, George, it looks like your challenge was proven wrong and seems like someone can successfully run a air compressor from a 12 volt inverter.

Here you go George