Hello David welcome to YT! Your method of replying is

correct. First off is the intention to have this as a

working forklift or do you have some other intention for

the engine to power something else. How did it run

before you put all the new parts on it? Is the electronic

distributor the CORRECT one for a 6 cylinder engine?

Does the distributor have a new rotor in it? If so how

does it compare to the old one? Others have given you

good suggestions as far as distributor cap etc. How do

the spark plugs in the cylinders that are not firing look?

Try swapping the spark plug between 1 and 3 does it

now fire on 1 but not 3? Then you have a spark plug

problem, are they gapped correctly? The suggestion of

a problem with the intake manifold sealing is a wise

thing to check. Spray carb cleaner or starting fluid at

the mating surfaces of the intake to the head. If the

engine changes speed or picks up the misfire then the

gasket is leaking. Very likely cause of some cylinder

firing and some not on an engine with good

compression. One other thing worth mentioning, is the

coolant holding a proper level? You say the head is

cracked from freezing. It may be holding on the

outside but what about the inside?

Now as for what Tramway guy said about the timing is

correct as far as connecting a timing light or static

timing with a test light. But for almost any other

process you do for timing use number 1 cylinder. Just

best for a novice to stick with conventional processes.

Timing a distributor to an engine should be done on

TDC of the compression stroke of number 1 cylinder.

It would be nice to see the exhaust problem you have

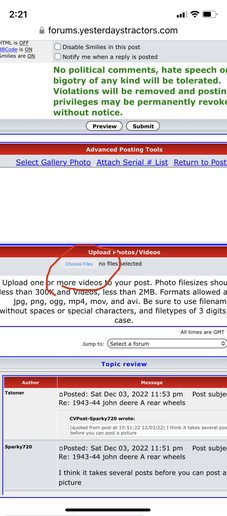

here is a run down of how to post photos.

Pictures post through the ..Browse or Choose files..

button just below where it says ..Upload

Photos/Videos.. down lower in the ..New post and reply

windows. See photo to see an example on my iPhone.

Clicking that will give you a choice to select the file or

folder the pictures are stored in on your PC or phone.

Then select the photo from the file and ..Add.. it. They

cannot be pasted into the text area as a file. I would

suggest only adding 1 or 2 per reply to see if your

photos are below the file size limit.