Jerry Cummins

New User

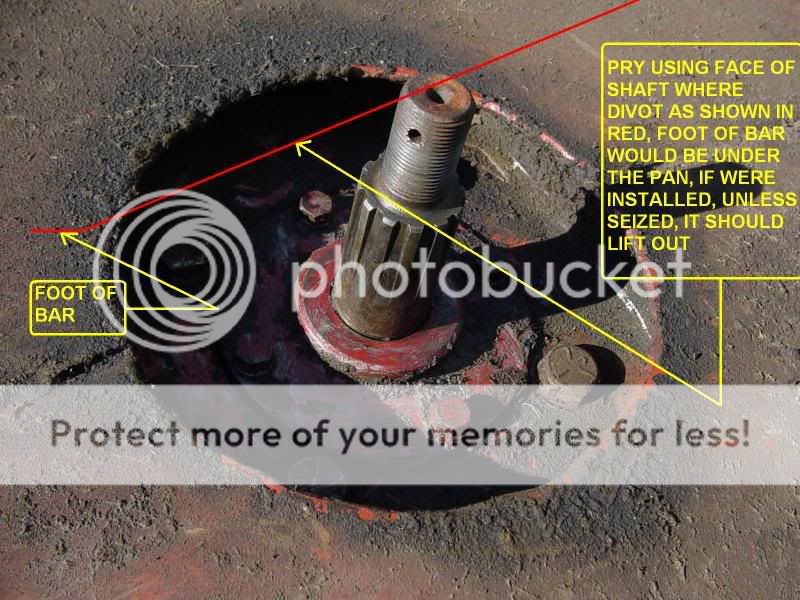

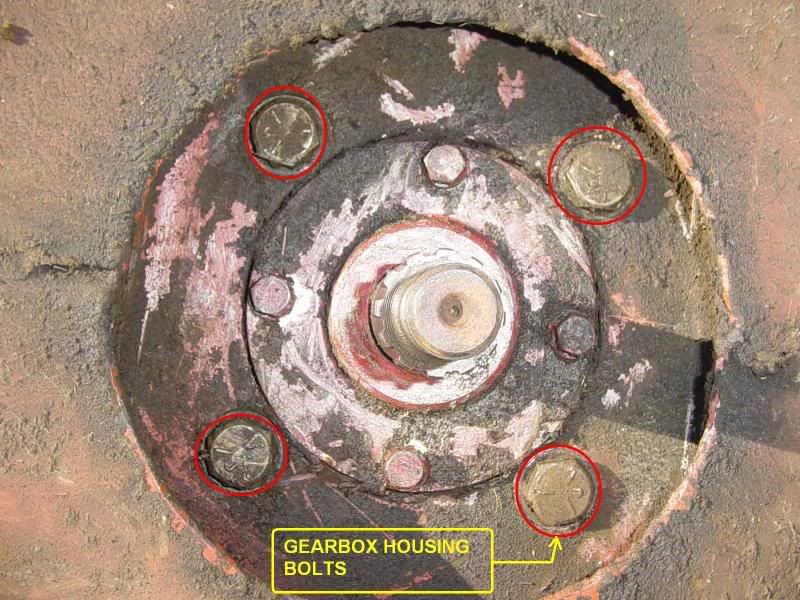

I have an older Servis (Rhino) batwing. While mowing yesterday, the entire pumpkin in the center portion dropped off. Doesn’t appear it’s damaged, even found the nut. Question is, how do I get that back on there. It’s heavy.

Probably have to disassemble the blades from the pumpkin, but even then, this could be a real struggle. Does it make sense to maybe upend the mower with FEL, so it’s vertical, then put it on?

Probably have to disassemble the blades from the pumpkin, but even then, this could be a real struggle. Does it make sense to maybe upend the mower with FEL, so it’s vertical, then put it on?