billonthefarm

Member

- Location

- Farmington IL

Ever since we took over this little cattle operation about a year ago we have had dreams of rebuilding the corral and making things easier for one person to work with the cows. The old corral was 34 years old and in serious need of updating. My friend nick knew he would have time off at the end of August so we had been planning this for awhile. Lots and lots of drawings and measuring, making changes and drawings and measuring again, went on before we even started.

The center piece to the entire plan. A new Stronghold tub. Tried to purchase a used one on a auction but it brought more than I paid for this new one and I couldnt get a For-most quick enough. A trip to quick Carthage and I had a tub and alley so we could begin.

We needed some big post and I was lucky enough to get in touch with the local REA coop and get used light poles for $15 a piece and we could pick the ones we wanted. Had to cut them in half to haul, one was 40 feet.

Talked about alot of different options for the fence. Ended up going with treated 2x8's cause it makes such a nice looking fence and is easy to modify. This is almost half of the boards we would need. No going to big box store, the local lumberyard was within $.07 per board in price so I was able buy close to home.

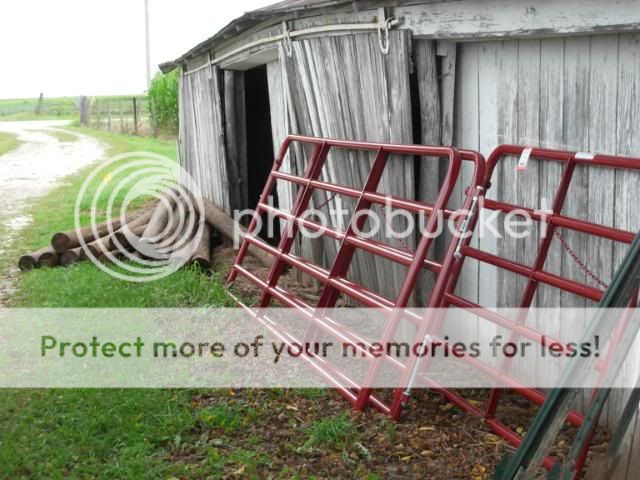

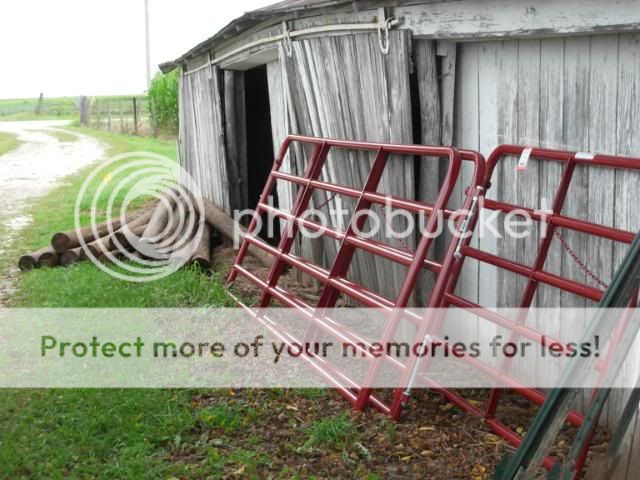

More supplies. Gates from TSC and some high priced post from the Farm King store.

Hard to believe it takes this much stuff to build fence! Well, that was most of it anyway.

The official post hole digging tractor. It is hard to comprehend the work involved when fence was put in by hand. Those guys knew what is was to work.

I'm not sure what the bottom 9 foot of a light pole weighs but its alot!

The finished project. Its not fancy, its not perfect and it cost quite a bit to get it done but if it keeps someone from getting hurt and we can save the occasional cow or calf because we can handle them so much easier then it will be bargin and well worth the time, effort and money.

There is about 75 feet of board fence in the lot so we can crowd them to the outside and get them in the pens. The first pen is 12x36. The second pen is 10x20. The chute in the pictures is our portable chute but we will actually set the other chute in as it has the automatic headgate and hopefully that will allow this whole thing to be a one man operation at calving time. The way it is now if we need to catch a cow and calf it takes at least two of us and that isnt very handy sometimes. We will be able to sort them off into the first pen, down the alley to load out or just back into the lot, and we will be able to send them to the barn straight from the chute and back from the barn into the pens without them going into the lots. I'll let you know how this works out!

We will put the finishing touches on it tomorrow, labor day, how ironic. Nick will go back to his office job at CAT on tuesday. After working two weeks of tweleve hour days on the farm for free he might be looking forward to it. Myself along with travis and cliff will begin to prepare for the coming harvest. Bins to clean and equipemnt to get serviced and ready to roll. We did have some really nice weather to work in and several people would stop in and check on our progress as we went along. Its always good to have supervision! A good job is done at last.

Last but certainly not least, wrigley says hey!

He enjoys the cattle just as much as I do.

bill

The center piece to the entire plan. A new Stronghold tub. Tried to purchase a used one on a auction but it brought more than I paid for this new one and I couldnt get a For-most quick enough. A trip to quick Carthage and I had a tub and alley so we could begin.

We needed some big post and I was lucky enough to get in touch with the local REA coop and get used light poles for $15 a piece and we could pick the ones we wanted. Had to cut them in half to haul, one was 40 feet.

Talked about alot of different options for the fence. Ended up going with treated 2x8's cause it makes such a nice looking fence and is easy to modify. This is almost half of the boards we would need. No going to big box store, the local lumberyard was within $.07 per board in price so I was able buy close to home.

More supplies. Gates from TSC and some high priced post from the Farm King store.

Hard to believe it takes this much stuff to build fence! Well, that was most of it anyway.

The official post hole digging tractor. It is hard to comprehend the work involved when fence was put in by hand. Those guys knew what is was to work.

I'm not sure what the bottom 9 foot of a light pole weighs but its alot!

The finished project. Its not fancy, its not perfect and it cost quite a bit to get it done but if it keeps someone from getting hurt and we can save the occasional cow or calf because we can handle them so much easier then it will be bargin and well worth the time, effort and money.

There is about 75 feet of board fence in the lot so we can crowd them to the outside and get them in the pens. The first pen is 12x36. The second pen is 10x20. The chute in the pictures is our portable chute but we will actually set the other chute in as it has the automatic headgate and hopefully that will allow this whole thing to be a one man operation at calving time. The way it is now if we need to catch a cow and calf it takes at least two of us and that isnt very handy sometimes. We will be able to sort them off into the first pen, down the alley to load out or just back into the lot, and we will be able to send them to the barn straight from the chute and back from the barn into the pens without them going into the lots. I'll let you know how this works out!

We will put the finishing touches on it tomorrow, labor day, how ironic. Nick will go back to his office job at CAT on tuesday. After working two weeks of tweleve hour days on the farm for free he might be looking forward to it. Myself along with travis and cliff will begin to prepare for the coming harvest. Bins to clean and equipemnt to get serviced and ready to roll. We did have some really nice weather to work in and several people would stop in and check on our progress as we went along. Its always good to have supervision! A good job is done at last.

Last but certainly not least, wrigley says hey!

He enjoys the cattle just as much as I do.

bill