Smarten_up

Member

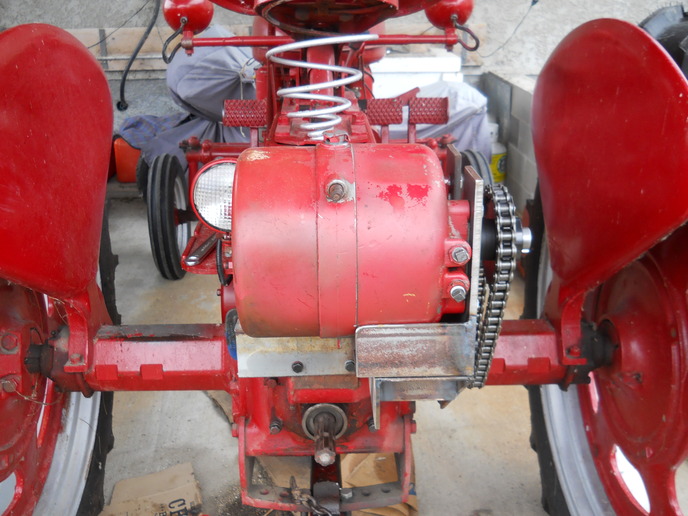

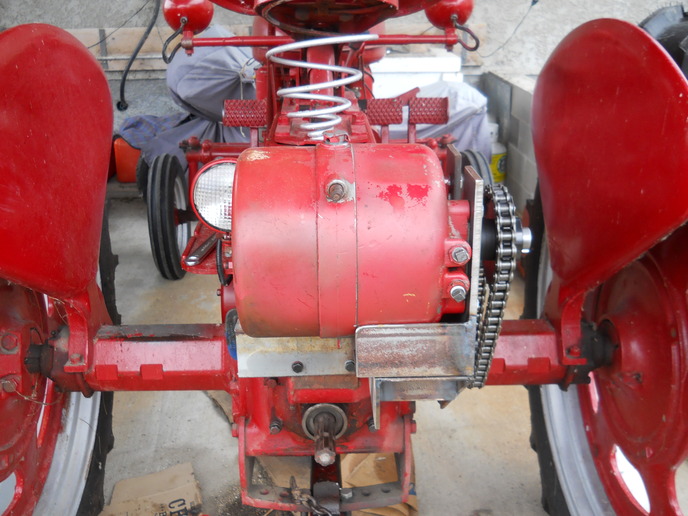

My Farmall C doesnt have a factory installed hydraulic system, but I have an old Char-Lynn E600 hydraulic pack. So for something challenging to do, and just because I thought some hydraulics could be useful on the C I decided I would install it on the tractor. Rather than driving the E600 from the PTO, I thought use the belt pulley drive (never use it anyway), frees up the PTO for other uses.

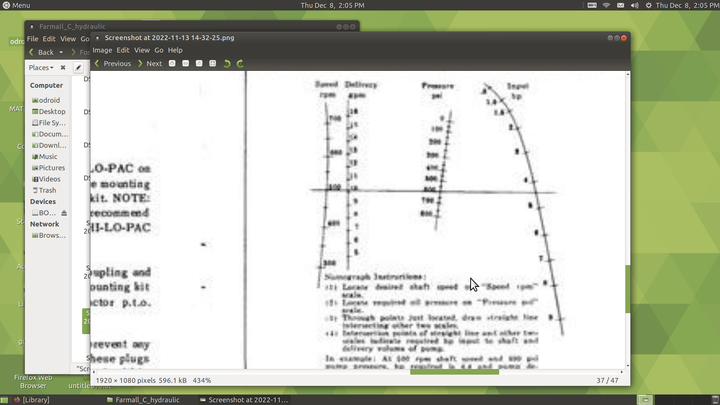

I dont have much info on the E600 (only some poor quality photos from the manual) so some guess work involved.

Had to clean up the E600 and make a few new parts for it to be put back in operation, new levers, chain drive, and a special mount to fit the C belt pulley.

Everything inside the E600 appears in very good shape, although found a lot of ants on the filter screen.

I have a few questions for anyone knowledgeable about this stuff.

1. Hydraulic pump 8gpm at 700psi and 450rpm, is that correct?

2. How does the single acting hydraulic port work? Does the weight of the implement push the hyd cylinder back when pressure is released? or...

Some pictures of the set-up so far.

I dont have much info on the E600 (only some poor quality photos from the manual) so some guess work involved.

Had to clean up the E600 and make a few new parts for it to be put back in operation, new levers, chain drive, and a special mount to fit the C belt pulley.

Everything inside the E600 appears in very good shape, although found a lot of ants on the filter screen.

I have a few questions for anyone knowledgeable about this stuff.

1. Hydraulic pump 8gpm at 700psi and 450rpm, is that correct?

2. How does the single acting hydraulic port work? Does the weight of the implement push the hyd cylinder back when pressure is released? or...

Some pictures of the set-up so far.