jon f mn

Well-known Member

Got Jeff's 2394 all together and running. Have to re-torque the heads tomorrow, was going to finish tonight but the torque wrench that Jeff borrowed fell apart so I'll have to get a different one in the morning to finish.

I want to thank some of the wonderful folks here who helped out. Nutty (Tom) and ACG (Loren) and 1370rod. Took a few calls to Loren and Tom and one to Rod, but we were able to get it done.

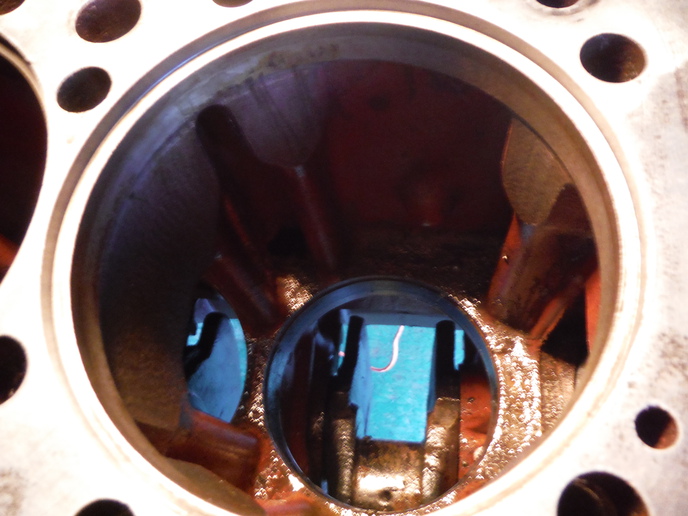

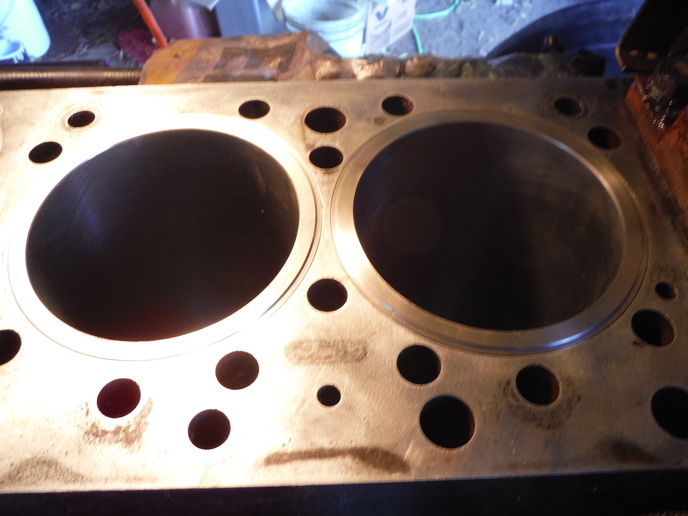

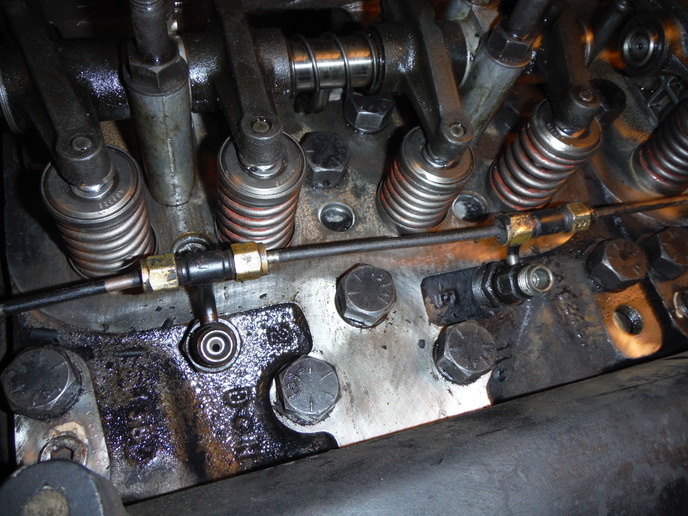

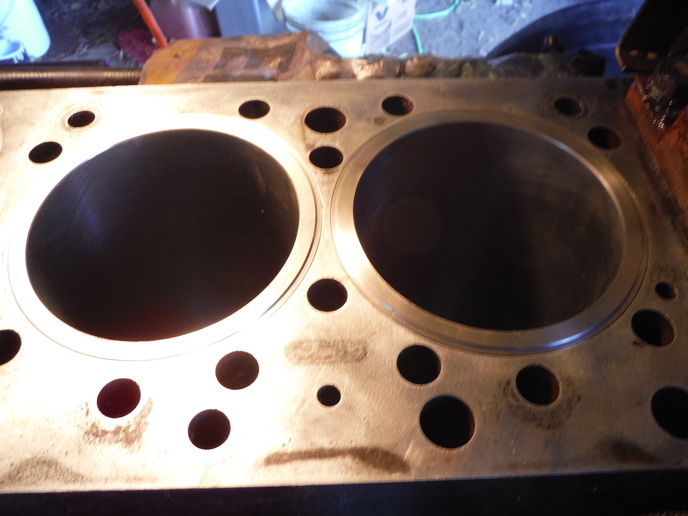

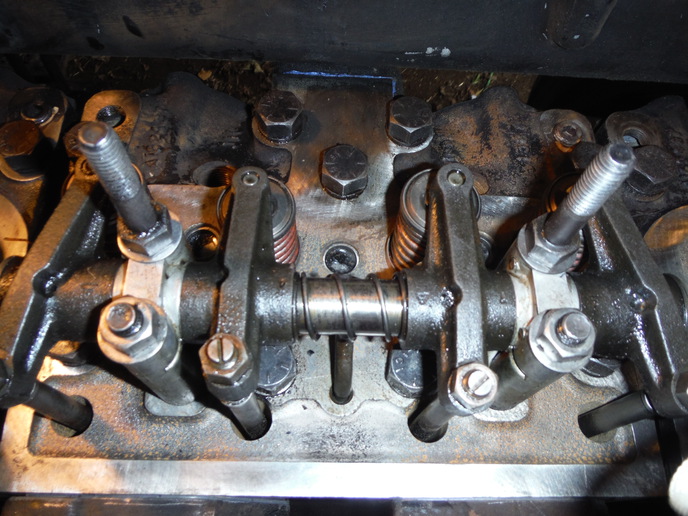

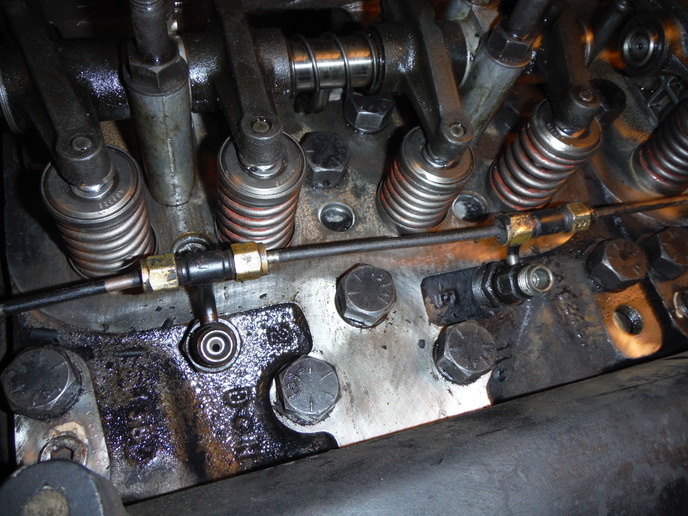

I am no master mechanic and wouldn't normally do a job like this for anyone else. There is too much risk that I would mess up and cost them money. In this case I did it for a good friend who couldn't do it himself. Also, Jeff just couldn't afford to hire it done so if I hadn't agreed to help he would just have been without a tractor. Had to work in his machinery shed with no heat and a dirt floor so it was cold sometimes and hard to keep stuff clean. Lighting, as you can see in the pics, was poor to say the least. But it was better than outside in the rain and snow we had today. We didn't have a parts washer or even a presure washer, so we didn't get to carried away with cleaning the outsides of all the parts. The oil pan and manifolds and such were cleaned inside and wire brushed outside. Was a bit cold to be washing parts in a pan of diesel, so we only did what we had too.

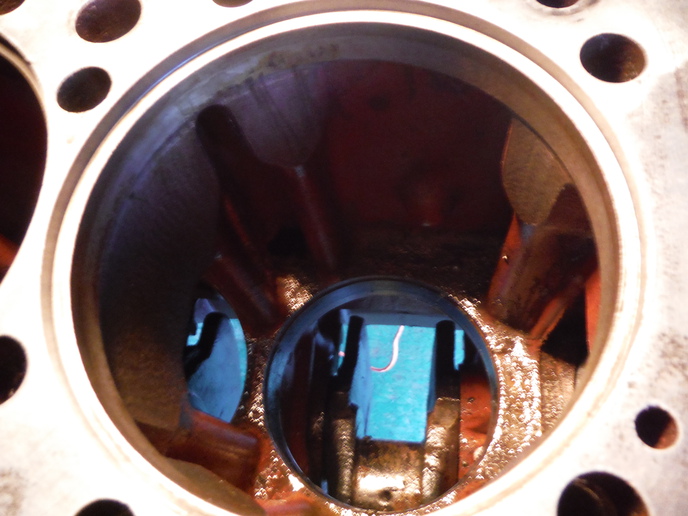

Over all it went pretty good, but we did have some problems. The kit didn't have the seal that goes between the oil pump and block, also came with a bad sleeve o-ring. So that meant a trip to the dealer. Had to make a trip to another friend of Jeff's for the torque wrench too.

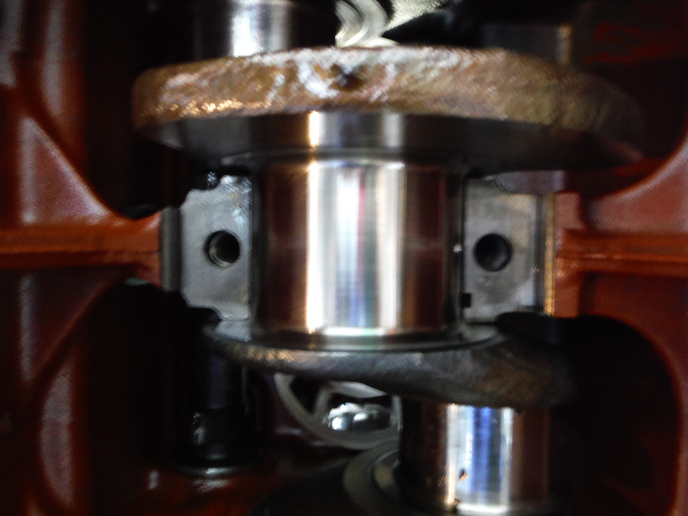

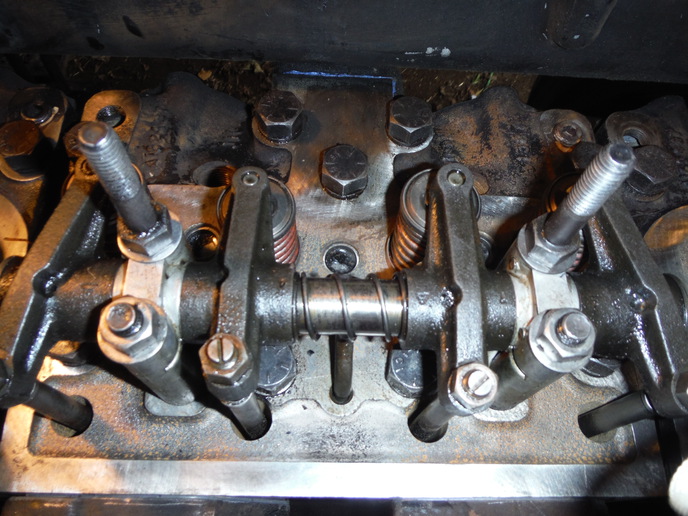

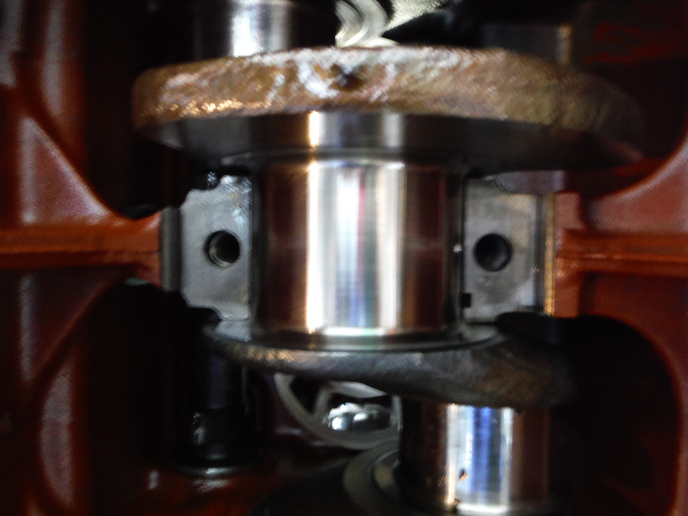

I did learn a few things along the way. 1, don't drop a main bearing bolt on your nose, I shed some blood on that one. 2, case made the rear main bolts so it's a (insert profanity here) to get a socket on to torque them past the rear main seal holder. 3, Who ever put those 12 point bolts up in, behind, under, around back of, beside, that cast piece at the back of the pan should be (insert another profanity here)repeatedly. 4, always check the number on the rods so you get them in the right holes the first time. Only got the first one wrong. 5, don't put the water manifold on til you get the injector lines on. 6, make sure you get ALL the injectors tight. If you don't it sounds just like a valve leaking and you can spend a bunch of time re-setting the rockers trying to find the tight one. 7, I don't know what case uses for gasket sealer, but you could hold a submarine together with that stuff. The oil pan and some other stuff it took a hammer and chisel to get it off.

Guess that's why a good mechanic is worth what they make. I can't imagine how funny it would have been for someone who knows what they are doing to have watched me stuggling along. lol.

Here are some pics of the process, the last is Jeff with his happy face because the tractor is actually running behind him lol Also a video of the first start up. Hope you enjoy.

[/url]http://www.youtube.com/watch?v=iQjwkbVEQsI

I want to thank some of the wonderful folks here who helped out. Nutty (Tom) and ACG (Loren) and 1370rod. Took a few calls to Loren and Tom and one to Rod, but we were able to get it done.

I am no master mechanic and wouldn't normally do a job like this for anyone else. There is too much risk that I would mess up and cost them money. In this case I did it for a good friend who couldn't do it himself. Also, Jeff just couldn't afford to hire it done so if I hadn't agreed to help he would just have been without a tractor. Had to work in his machinery shed with no heat and a dirt floor so it was cold sometimes and hard to keep stuff clean. Lighting, as you can see in the pics, was poor to say the least. But it was better than outside in the rain and snow we had today. We didn't have a parts washer or even a presure washer, so we didn't get to carried away with cleaning the outsides of all the parts. The oil pan and manifolds and such were cleaned inside and wire brushed outside. Was a bit cold to be washing parts in a pan of diesel, so we only did what we had too.

Over all it went pretty good, but we did have some problems. The kit didn't have the seal that goes between the oil pump and block, also came with a bad sleeve o-ring. So that meant a trip to the dealer. Had to make a trip to another friend of Jeff's for the torque wrench too.

I did learn a few things along the way. 1, don't drop a main bearing bolt on your nose, I shed some blood on that one. 2, case made the rear main bolts so it's a (insert profanity here) to get a socket on to torque them past the rear main seal holder. 3, Who ever put those 12 point bolts up in, behind, under, around back of, beside, that cast piece at the back of the pan should be (insert another profanity here)repeatedly. 4, always check the number on the rods so you get them in the right holes the first time. Only got the first one wrong. 5, don't put the water manifold on til you get the injector lines on. 6, make sure you get ALL the injectors tight. If you don't it sounds just like a valve leaking and you can spend a bunch of time re-setting the rockers trying to find the tight one. 7, I don't know what case uses for gasket sealer, but you could hold a submarine together with that stuff. The oil pan and some other stuff it took a hammer and chisel to get it off.

Guess that's why a good mechanic is worth what they make. I can't imagine how funny it would have been for someone who knows what they are doing to have watched me stuggling along. lol.

Here are some pics of the process, the last is Jeff with his happy face because the tractor is actually running behind him lol Also a video of the first start up. Hope you enjoy.

[/url]http://www.youtube.com/watch?v=iQjwkbVEQsI