Bryce Frazier

Well-known Member

Alright boys, how do I translate this? Not really sure what it means! Top left corner says # per bu (i think bu is bushel right)

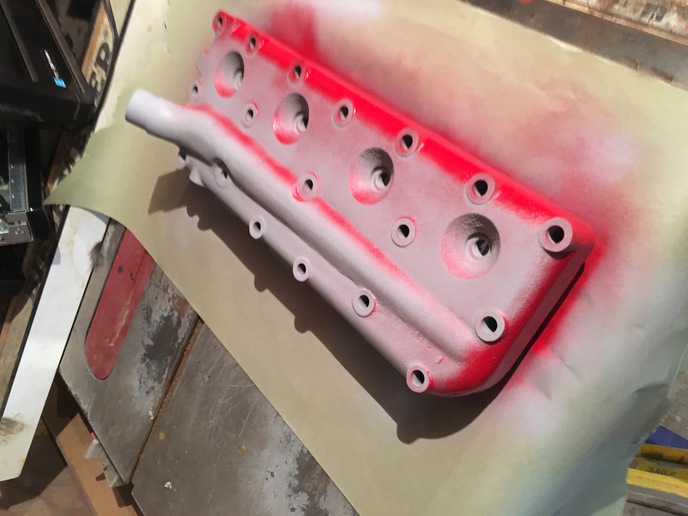

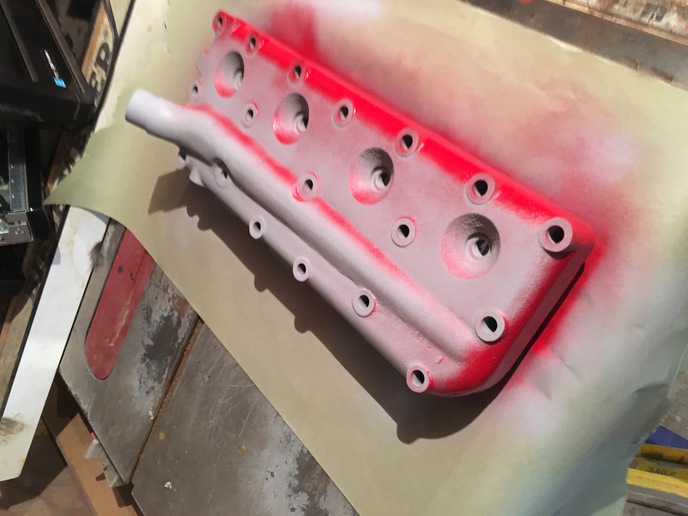

Here is another picture of the drill.

Also, on the back of the seed box, there are two arms that are adjustable, with numbers, which are represented in the chart above, both arms are at 35, but when you look inside the drill one set of feeder gears is about half way open, and the other is nearly all the way open? Sooo, what is wrong? I am assuming that something inside one of the arms is stripped/hogged out, but which one is right and which is wrong?!?! Here are some pictures of those too. Thanks for the info Case Nutty, and Adirondack case guy! Bryce

Here is another picture of the drill.

Also, on the back of the seed box, there are two arms that are adjustable, with numbers, which are represented in the chart above, both arms are at 35, but when you look inside the drill one set of feeder gears is about half way open, and the other is nearly all the way open? Sooo, what is wrong? I am assuming that something inside one of the arms is stripped/hogged out, but which one is right and which is wrong?!?! Here are some pictures of those too. Thanks for the info Case Nutty, and Adirondack case guy! Bryce