john in la

Well-known Member

A good selling point for mower salesmen is the blade spindles on the riding / zero turn deck are greaseable.

Keeps the spindle bearings from wearing out.

So how many of you grease this grease fitting???

Now for those of you that are willing to admit you grease the spindle bearings.

Did you really do any good or just waste your time???

Now to the point.

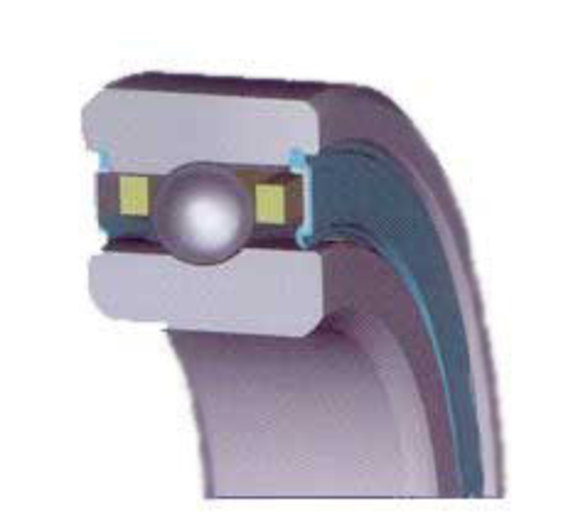

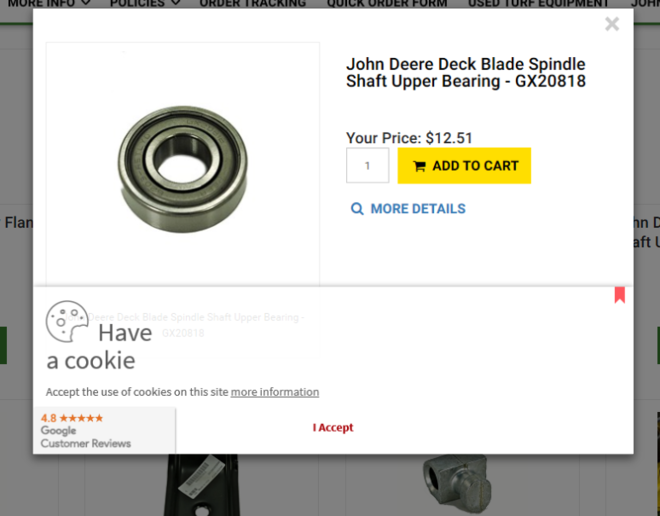

Can someone explain to me how putting grease into the spindle housing does any good when the bearings are sealed???

Keeps the spindle bearings from wearing out.

So how many of you grease this grease fitting???

Now for those of you that are willing to admit you grease the spindle bearings.

Did you really do any good or just waste your time???

Now to the point.

Can someone explain to me how putting grease into the spindle housing does any good when the bearings are sealed???