Christopher S.

Member

Good Afternoon Gentlemen, I'm looking into building my own skid loader box grader attachment. I plan to use this on my driveway to make the driving surface a bit more consistent. I have basically all the material I need on hand. The part that I was unsure of was the depth of the cutting edge in relation to the skids. Should they be level, should they be lower (by how much) or should I go through the effort to make them adjustable. Any input you gentlemen have would be appreciated. Thanks

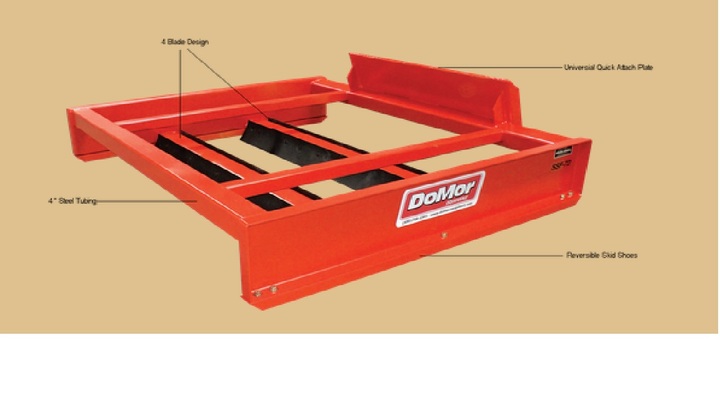

(the picture is what I was using as a rough plan)

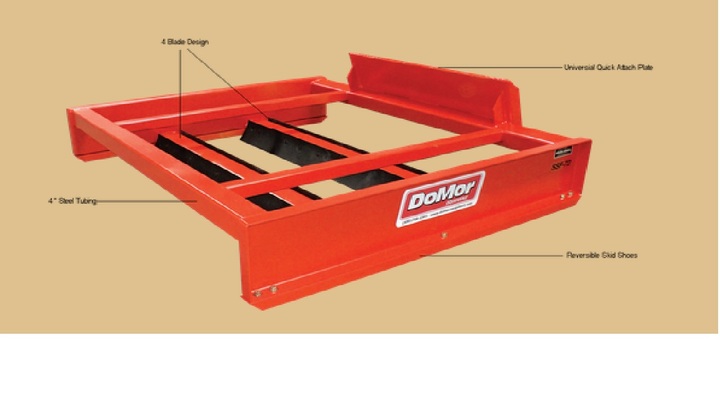

(the picture is what I was using as a rough plan)